Product Details

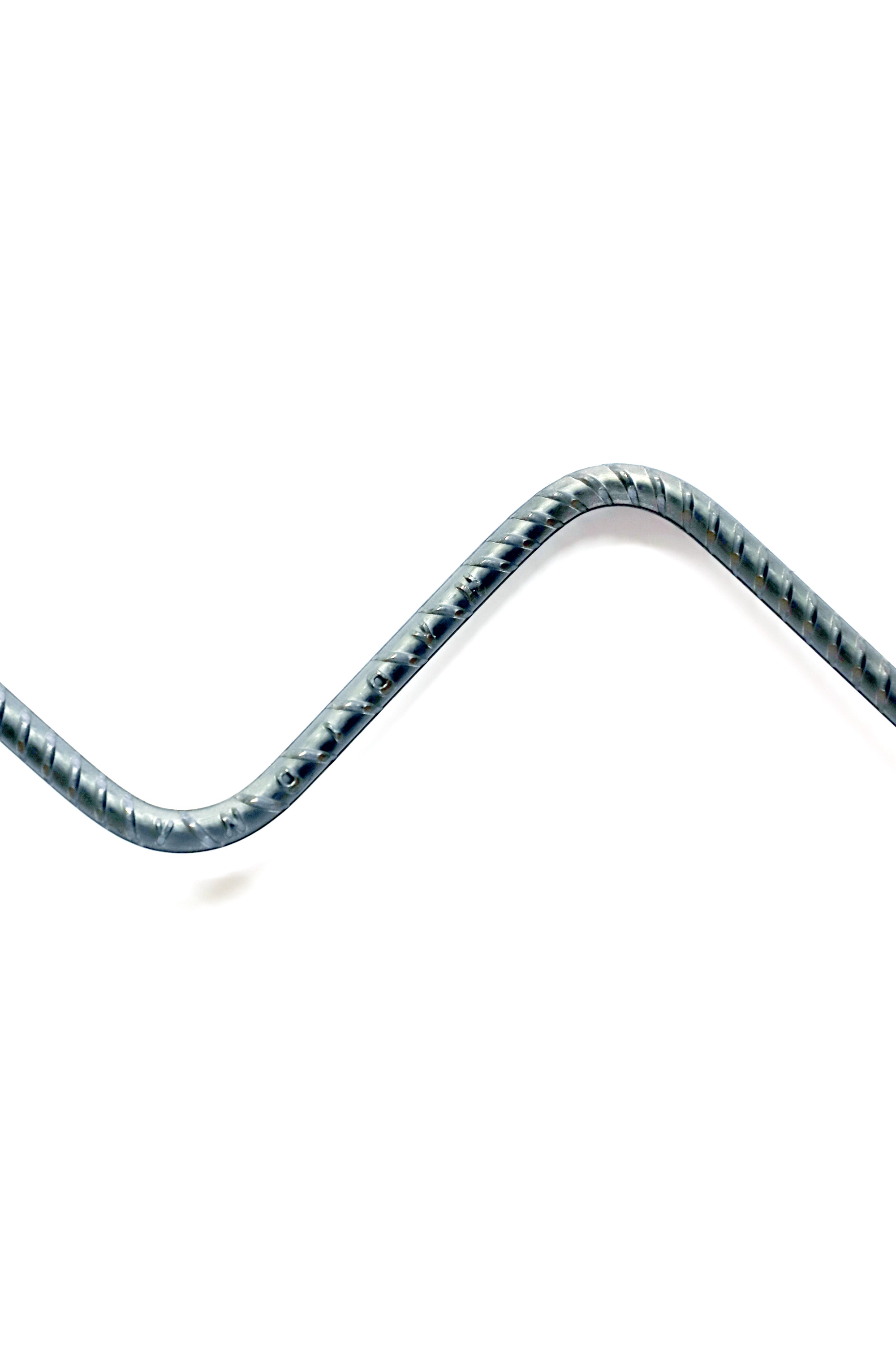

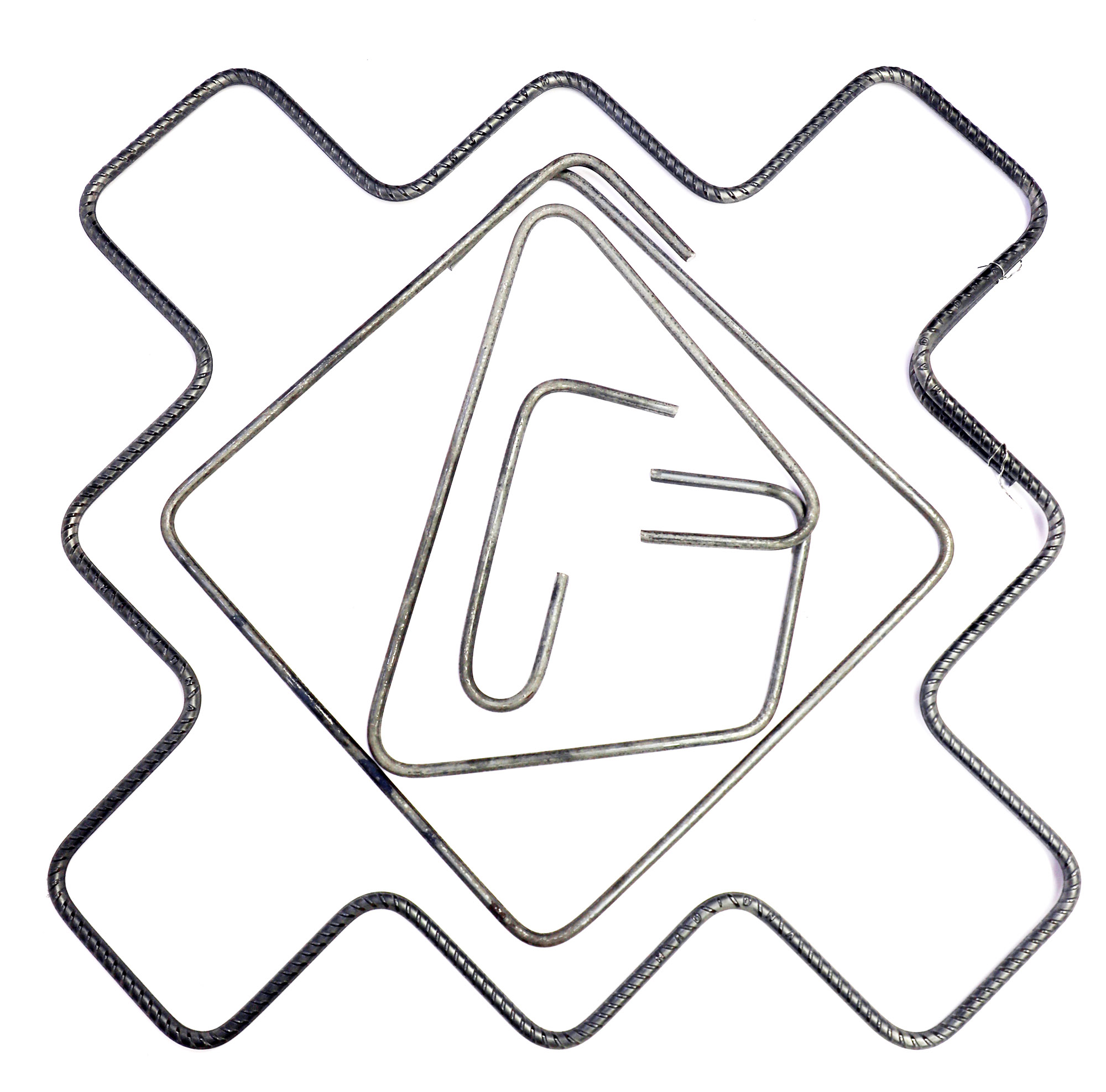

Cutting and bending, supplied by the leading Italian MEP group in this field, enables us to deliver cut and folded bars between 6 and 40 mm in diameter, "at the appropriate time" to the construction site, according to detailed contractor plans.

SSC offers cut and bent bars through a JIT (just in time) delivery system at the contractor`s construction site, according to their blueprints and in compliance with schedules and individualized bundle.

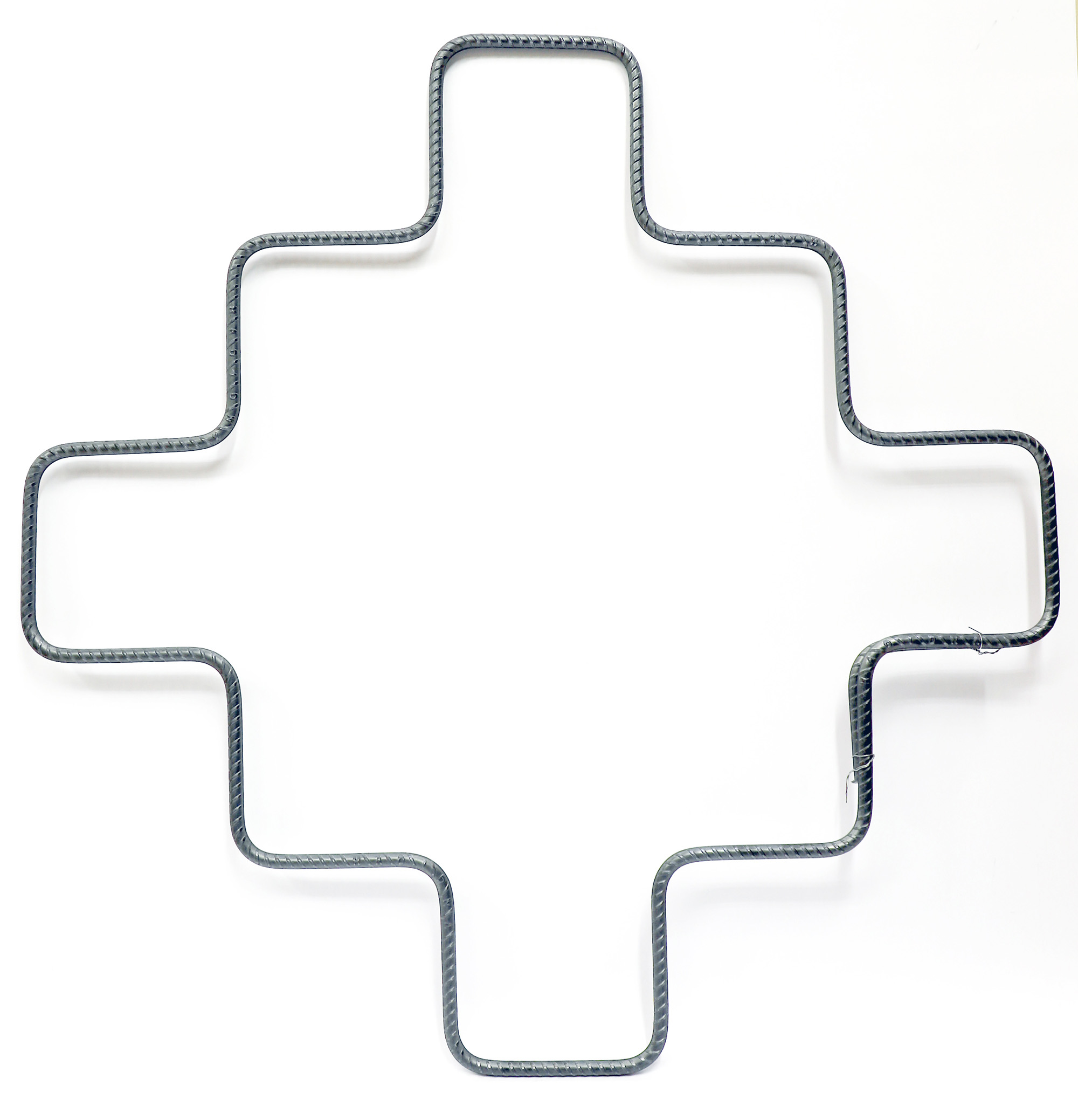

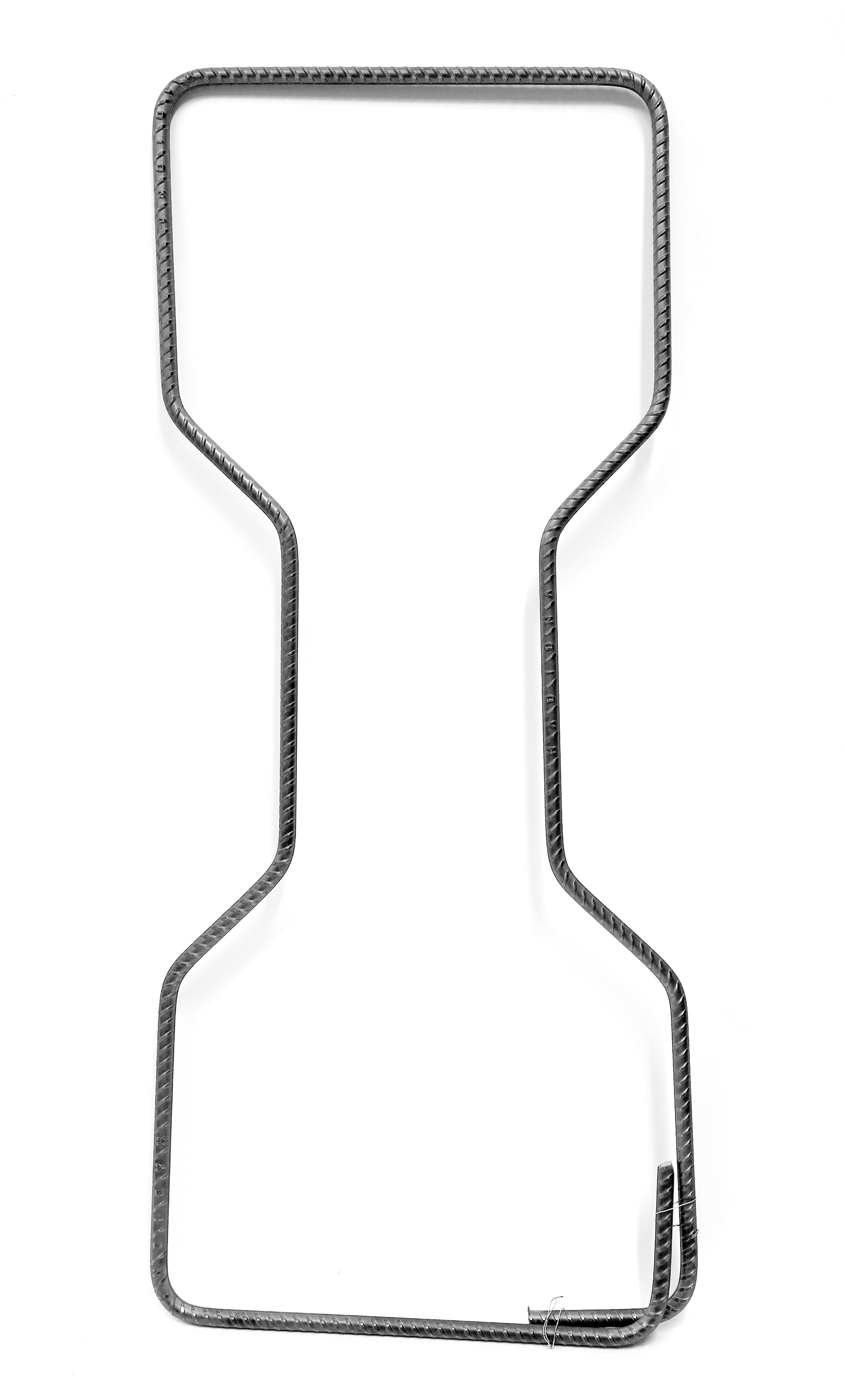

The cut & bend division produces shapes and stirrups in the required lengths and bent shapes for use in reinforced concrete structures. The production process is automated through the use of specialized machinery to enable high volume production with minimum labor requirements.

| CUT & BEND TRADITIONAL SYSTEM | PROJECT DESIGN | MATERIALS PROCUREMENT | CONSTRUCTION | CONSTRUCTION | COST | |||||||||||

| * ESTIMATE STEEL CONSUMPTION | * ESTIMATE STEEL

CONSUMPTION * AIM TO REDUCE WASTE * GET A STEEL PRICE QUOTATION PURCHASE PLANNING DONE MANY WEEKS AHEAD * AIM TO REDUCE WASTE |

* EMPLOY LABORS TO DO THE CUT BEND SERVICE ON-

SITE * PURCHASECUT BEND EQUIPMENT * FIND SPACE FOR PROCESSINGAND STORAGE |

* MANDATORY QUALTY CONTROL * LOW PRODUCTION CAPACITY DUE TO EQUIPPMENT AND LABOR PRODUCTIVITY * CONTROL OF WASTE |

UNKNOWN STEEL CONSUMPTION UNTIL PROJECT COMPLETION | ||||||||||||

| CUT & BEND BARS FROM SSC | *PREPARE CUT& BEND BLUEPRINTS | *ASK FOR A PRICE QUOTATION OF CUT & BENT BARS | *CHOOSE DELIVERY DATE ACCORDING TO NEED | * POSSIBILITY OF RESCHEDULING DELIVERIES | * KNOWLEDGE OF THE EXACT STEEL CONSUMPATION FROM THE BEGINNING | |||||||||||

| The advantages To Contractors | ||||||||||||||||

| Through its post-sale service, SSC provides an on-going follow-up service at each construction site, performed by a team of professionals of the highest level. | ||||||||||||||||

| Contractors are aware of the advantages of purchasing cut & bent steel versus bending it on site. Cut & bend is more advantageous because it: | ||||||||||||||||

| * Minimizes production costs through reduction of labor cost. | ||||||||||||||||

| * Eliminates waste; estimated at 5 to %8 from steel value. | ||||||||||||||||

| * Saves time and eliminates production errors, higher productivity and more accurate than manual on-site cut and bend. | ||||||||||||||||

| * Reduces financial costs. | ||||||||||||||||

| * Minimizes required storage space. | ||||||||||||||||

| * Reduces bar theft on site and double handling | ||||||||||||||||

| PRODUCTION COSTS | CUT & BEND TRADITIONAL SYSTEM | CUT & BEND BARS FROM SSC | ||||||||||||||

| ESTIMATE STEEL CONSUMPTION AIM TO REDUCE WASTE |

NO ASSOCIATED PROCESSING COST NO CUT & BEND EQUIPMENT | |||||||||||||||

| WASTE | VARIES BETWEEN 5 AND 8% | CUSTOMER ONLY PAYS FOR THE THEORETICAL BLUEPRINT WEIGHT AND NOT FOR WASTE PROCESSING | ||||||||||||||

| TIME | TIME CONSUMING | TIME SAVING | ||||||||||||||

| FINANCIAL COSTS | HIGH COST AS THE MATERIAL IS PURCHASED AND INVOICED VERY EARY ( 1 WEEK PROCUREMENT + 2 WEEKS STORAGE | LOWER COST AS THE INVOICE IS ISSUED ON THE DAY OF DELIVERY WHICH IS THE UTILIZATION DATE | ||||||||||||||

| MATERIAL ORDERED WHEN NEEDED > FREE UP STORAGE AREA | ||||||||||||||||

| STORAGE AREA & AVAILABILITY | STORAGE AREA NEEDED AND STORAGE AVAILABILITY LIMITED | |||||||||||||||

| OPERATION & SAFETY | HANLING OF LONG RE-BARS WITH RISKS OF ACCIDENTS | REDUCTION OF ACCIDENTS REDUCTION OF THEFT | ||||||||||||||